| Taiwan | Grain Size:0.6-0.8UM | |

| Long Shank Type | Series:Economical Series | |

| 100mm | Dia:4mm | |

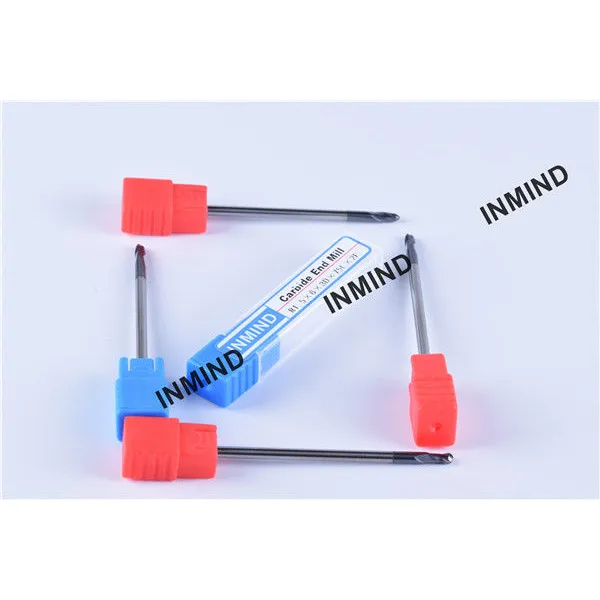

| 3500N/mm2 | Name:Ball End Mill Cutter | |

Long end mill,extra long carbide end mills |

||

Quick Detail:

0.6-0.8um Mirco grain size solid carbide rod

TIALN Coating ,high Aluminium (Black),Middle Aluminium(Purple)

Made by 5 AXIS CNC grinder

Checked by Zoller Inspection Equipment

Workpiece upto HRC50

1 piece packing.

Standard Type

Description:

Micro Grain Szie 0.6-0.8um, Wc carbide rod with high tenacity,with high quality TiAlN coating,getting long tool life,from roughing to finishing processing,reduce time of changing cutters,improving efficency of machine,saving time of making moulds.Suggest to process iron and steel upto HRC50,Middle-low speed.

Carbide Rod:Wc:90%,Co:10%,TRS:3800N/mm2, Grain Size:0.6-0.8um

Applications:

Fit for milling quenching and tempered steel.stainless steel.nickel alloy and Titanium alloy,Cast iron,enhanced composited material with fiberglass,Also fit for milling copper.

Description:

Ultra-Fine Grain Szie 0.5-0.6um, Wc carbide rod with high tenacity,with high quality TiAlN coating,getting long tool life,from roughing to finishing processing,reduce time of changing cutters,improving efficency of machine,saving time of making moulds.Suggest to process iron and steel upto HRC55,Middle-High speed.

Carbide Rod:Wc:88%,Co:12%,TRS:4000N/mm2, Grain Size:0.5-0.6um

Specifications:

| Order No | Cutting Diameter | Flute Length | Shank Diameter | A.O.L |

| d | l | D | L | |

| R1.5×6×3D×75L×2F | 3 | 6 | 3 | 75 |

we also have other standard size: 1mm to 20mm

| Order No | Cutting Dia | Shank | Cutting Length | AOL |

| d | D | l | L | |

| R0.5×2×4D×75L×2F | 1 | 4 | 2 | 75 |

| R0.75×3×4D×75L×2F | 1.5 | 4 | 3 | 75 |

| R1.0×4×4D×75L×2F | 2 | 4 | 4 | 75 |

| R1.25×5×4D×75L×2F | 2.5 | 4 | 5 | 75 |

| R1.5×6×4D×75L×2F | 3 | 4 | 6 | 75 |

| R1.75×7×4D×75L×2F | 3.5 | 4 | 7 | 75 |

| R2.0×8×4D×75L×2F | 4 | 4 | 8 | 75 |

| R2.5×10×6D×75L×2F | 5 | 6 | 10 | 75 |

| R2.5×10×6D×100L×2F | 5 | 6 | 10 | 100 |

| R3.0×12×6D×75L×2F | 6 | 6 | 12 | 75 |

| R3.0×12×6D×100L×2F | 6 | 6 | 12 | 100 |

| R3.0×12×6D×150L×2F | 6 | 6 | 12 | 150 |

| R4.0×16×8D×75L×2F | 8 | 8 | 16 | 75 |

| R4.0×16×8D×100L×2F | 8 | 8 | 16 | 100 |

| R4.0×16×8D×150L×2F | 8 | 8 | 16 | 150 |

| R5.0×20×10D×100L×2F | 10 | 10 | 20 | 100 |

| R5.0×20×10D×150L×2F | 10 | 10 | 20 | 150 |

| R6.0×24×12D×100L×2F | 12 | 12 | 24 | 100 |

| R6.0×24×12D×150L×2F | 12 | 12 | 24 | 150 |

| R7.0×28×14D×150L×2F | 14 | 14 | 28 | 150 |

| R8.0×32×16D×150L×2F | 16 | 16 | 32 | 150 |

| R10×40×20D×150L×2F | 20 | 20 | 40 | 150 |

Competitive Advantage:

Good and Stable Quality.

New Coating TiSiAlN Improve the performance in high hardness material and stainless steel.

Competitive price.

Help the agent to get the get more large market in the quality products.

Our production capacity

| Production Equipment | Machine Quantity | Product Name | Production Nersonnel | Monthly Output |

| German Walter | 2 | Tungsten Steel Drill,Endmill,Reamer,Thread Mill | Engineer: 2 Poduction staff: 6 | 20000PCS |

| Australia ANCA | 3 | Tungsten Steel Drill,Endmill,Reamer,Thread Mill | Engineer: 2 Poduction staff: 4 | 30000PCS |

|

Germany Michael Deck |

2 | Tungsten Steel Endmill,Reamer | Engineer: 2 Poduction staff: 4 | 20000PCS |

FAQ:

1. Are you manufacturer? Do you have factory?

We are manufacturer, factory located in Changzhou City, Jiangsu Province, welcome to visit our factory!

2. What machine you use?

You can see Walter grinding machines and Zoller detection machine in our factory.

3. Do you provide free shipping?

We do not provide any shipping service, but you can get some discount if you order large quantity.

4. Can you send products to our Forwarder in China?

It is my pleasure to send your order to him/her

5. How about the OEM?

We can provide OEM service, and can laser your brand mark

6. How about the delivery time?

According to the sizes and quantity, delivery time is different. Usually be 5~10 days. We can tell you exact inventory state if you need.

7. Can you produce other size?

Yes, we can produce according your demand.

Our Service

1. Free samples will be available for most of the products .

2. 24 hours online to ensure your inquiry will be replied within 12 hours .

3. Most products can be delivered within 7 days after order.

4. Small trial order can also be accepted.

5. Customized Size & Coating as your requirement .

6. Quality Inspection---We inspect each pcs

7. If you are not sure about what exactly you need - feel free to contact us anytime and get professional assistance from us.

Contact : 24-hour online service

| Name |

Patrick.Yin |

|

patrick@inmind.com.cn |

|

| Skype |

patrick.yin |

|

4102512 |

|

|

13801792622 |

|

|

86-13801792622 |

|

| Telephone |

86-13801792622,13801503379 |

HRC50 BALL NOSE END MILLS's PDF CATALOG 3-4.pdf