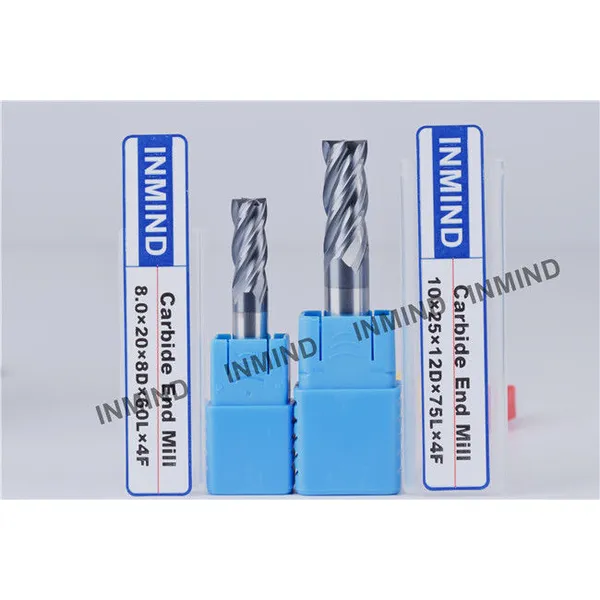

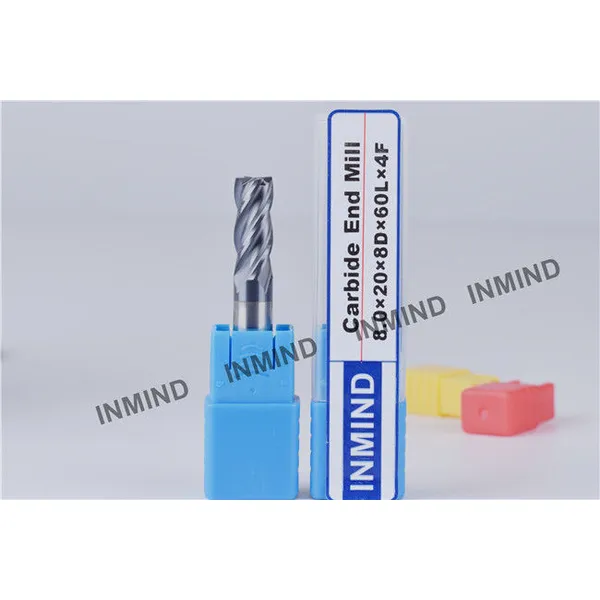

| Square End Mill | Grain Size:0.8UM | |

| ALTIN Or TiAlN | Standard:Taiwan | |

| 60mm | Colour:Black | |

| Standard Type | Diameter:8mm To12mm | |

solid carbide cutting tools,carbide end mill bits |

||

Description:

| The name of product | Solid Carbide End Mills & Tungsten Carbide HRC45 End Mill |

| Type |

solid carbide R endmills,solid carbide flattened endmills solid carbide ball nose endmills |

| Model Number | Various |

| Helix angle | 35 °,45° |

| Place of Origin | Jiangsu,China (Mainland) |

| Usage | Milling cutter |

| Advantage | Best quality along with reasonable prices |

| HRC | 45°,55°,65° |

| Brand Name | INMIND |

| Material | Tungsten Carbide |

| Coating | AlTiN,TIALN,TISIN |

| Free sample | Yes |

| OEM&ODM | Acceptable |

| The label of product | According to customer designation |

| Min.Order Quantity | 10 Piece/Pieces |

| FOB Price | Send an inquiry |

| Term of delivery | within one week, depends on inventory |

| Payment Ways | T/T,WEST UNION,PAYPAL,Alipay. |

Quick Detail:

0.6-0.8um Ultra-Fine grain size solid carbide end mill

TIALN Coating (Purple),TiSiAlN(Copper), AlTiN ( Black)

Made by 5 AXIS CNC grinder

Checked by Zoller Inspection Equipment

Workpiece upto HRC50

1 piece packing.

Standard Length Type

Carbide Rod:Wc:90%,Co:10%,TRS:3500N/mm2, Grain Size:0.6-0.8um

| Coating Paramter | ||||

| Item | ALTiN | TiALN | TiSiN | nACo |

| Hardness(HV) | 3200 | 2800 | 3600 | 4000 |

| Thickness(UM) | 2.5-3 | 2.5-3 | 3 | 3 |

| Oxidation | 900 | 800 | 1000 | 1200 |

| Friction | 0.3 | 0.3 | 0.45 | 0.4 |

| Colour | Black | Violet | Copper | Blue |

Applications:

Fit for milling quenching and tempered steel.stainless steel.nickel alloy and Titanium alloy,Cast iron,enhanced composited material with fiberglass,Also fit for milling copper.

Specifications:

| Order No | Cutting Dia | Cutting Length | Shank | AOL |

| d | l | D | L | |

| 8.0×20×8D×60L×4F | 8 | 20 | 8 | 60 |

We also supply other standard type square end mills.

| Order No | Cutting Dia | Cutting Length | Shank | AOL |

| d | l | D | L | |

| 1.0×3×4D×50L×4F | 1 | 3 | 4 | 50 |

| 1.5×4×4D×50L×4F | 1.5 | 4 | 4 | 50 |

| 2.0×6×4D×50L×4F | 2 | 6 | 4 | 50 |

| 2.5×8×4D×50L×4F | 2.5 | 8 | 4 | 50 |

| 3.0×8×4D×50L×4F | 3 | 8 | 4 | 50 |

| 3.5×10×4D×50L×4F | 3.5 | 10 | 4 | 50 |

| 4.0×11×4D×50L×4F | 4 | 11 | 4 | 50 |

| 3.0× 8×6D×50L×4F | 3 | 8 | 6 | 50 |

| 3.5×10×6D×50L×4F | 3.5 | 10 | 6 | 50 |

| 4.0×11×6D×50L×4F | 4 | 11 | 6 | 50 |

| 4.5×13×6D×50L×4F | 4.5 | 13 | 6 | 50 |

| 5.0×13×6D×50L×4F | 5 | 13 | 6 | 50 |

| 5.5×13×6D×50L×4F | 5.5 | 13 | 6 | 50 |

| 6.0×15×6D×50L×4F | 6 | 15 | 6 | 50 |

| 7.0×16×8D×60L×4F | 7 | 16 | 8 | 60 |

| 8.0 ×20×8D×60L×4F | 8 | 20 | 8 | 60 |

| 9 ×20×10D×75L×4F | 9 | 20 | 10 | 75 |

| 10×20×10D×75L×4F | 10 | 25 | 10 | 75 |

| 11×25×12D×75L×4F | 11 | 25 | 12 | 75 |

| 12×30×12D×75L×4F | 12 | 30 | 12 | 75 |

| 14×35×14D×100L×4F | 14 | 35 | 14 | 100 |

| 16×40×16D×100L×4F | 16 | 40 | 16 | 100 |

| 18×45×18D×100L×4F | 18 | 40 | 18 | 100 |

| 20×45×20D×100L×4F | 20 | 45 | 20 | 100 |

Competitive Advantage:

Good and Stable Quality.

New Coating TiSiAlN Improve the performance in high hardness material and stainless steel.

Competitive price.

Help the agent to get the get more large market in the quality products.

Warm tips for using end mills

In order to have a good cutting surface and extend the cutting tools life, a tool holder with high precision, high rigidity and good dynamic balance is required.

1. Measure the runout of the cutting tools before using, and if the runout is more than 0.01mm, please readjust it first.

2. The shorter of the length of the stick-out cutting tools is, the better the effect is. If the stick out part is too long, please readjust the rotate speed, feeding speed and cutting output.

3. When hearing unusual sound during the cutting process, please slow down the principle axis' rotate speed and the cutting output until the unusual sound is disappeared.

4. Cooling the steel in a spraying way can maximize the TiALN's effect. Water-soluble cutting fluid is not suitable for stainless steel, titanium alloy and heat resisting alloy.

5. Cutting method is selected according the type of the workpiece and machine. The above information is provided for informational purpose only.

Why choose us?

♦ Professional Service : We have been doing international business several years,we know how to behave ourselves

♦ Full experience of manufacturing: with more than 10 years in making cutting tools and also many years of OEM and ODM.

♦ High quality:We are supplier of mould industry, IT mobile industry , Automobile industry

♦ Most reasonable Price: We use the best material but give the best price as we can.

♦ Prompt Shipment: we shall pay most attention to your purchase order and will ensure shipment as soon as possible.

Company Information:

INMIND TOOLS is engaged in manufacturing carbide end mills and other metal cutting tools

We have been making end mills for more than 10 years with full and professional experience

Our R&D team innovate new items every year to meet customers' and market's requirements.

Our products are strictly inspected by Zoller before delivery.

We also accept SGS on-site inspection or 3rd party authorized inspection.

Our products meet Taiwan, Germany Standard requirements.

We have a strong innovation team.

If you have any idea for new products, please contact us, we will make you satisfied.

Our service: How to order?

1 Customers send detailed inquiry to us by email

2 We reply with price, specifications, packing, photos, and other details.

3 Both of us agree the price and confirm the details.

4 We write the proforma invoice and send to customers.

5 Customers make deposit.

6 We make mass production samples.

7 We send mass product samples or send photos to customers for approval.

8 Customers confirm the mass production samples.

9 We start mass production.(we have huge stock for most standard end mills)

10 We show ready products' photos or customers inspect on site.

11 Customers make balance payment.

12 Delivery is arranged. Feedback from customers for better work in future.

FAQ:

1. Q: What's MOQ?

A: MOQ is 200pcs

2. Q: Do you accept trial order less than 200pcs

A: Yes, we do. Please contact us for trial order.

3. Q: Can we get samples?

A: Yes, we can provide regular samples free of charge.

4. Q: What's the lead time for customized sample and sample charge?

A: Lead time for customized sample: 3days; Sample charge: US$17

5. Q: What's the lead time for regular order?

A: 12~15days for order quantity lower than 5000pc; For more quantity, please conact us for lead time.

6. Q: What's your quality assurance?

A: We have quality warranty 1 year.

7. Q: Do you accept OEM or ODM order?

A: Yes, we accept. We can disscuss on specific case.

8. Q: What's shipping terms:

A: We can do Ex-works, express door to door, FOB, CIF.

Payment:

T/T ,Western Union, or the other ways

Shipping:

1. Ex-works: We can offer ex-works price if you have your own shiping agent.

2. Express door to door: We can get very competative price as we have contract with DHL, UPS, FedEx, TNT, etc.

3. FOB price: For big order, FCL, LCL, we can offer you FOB Shenzhen, or FOB Shanghai price.

4. CIF price: We also can offer you CIF price upon your appointed forarder.

5. Others: For other shipping terms, we can discuss and find the best solution for order shipping.

Contact : 24-hour online service

| Name | Patrick.Yin |

|

patrick@inmind.com.cn |

|

| Skype |

patrick.yin |

|

4102512 |

|

| 13801792622 | |

|

86-13801792622 |

|

| Telephone |

86-13801792622,13801503379 |