| 8 | Grain Size:0.6UM | |

| Copper | Coating:TiSiN | |

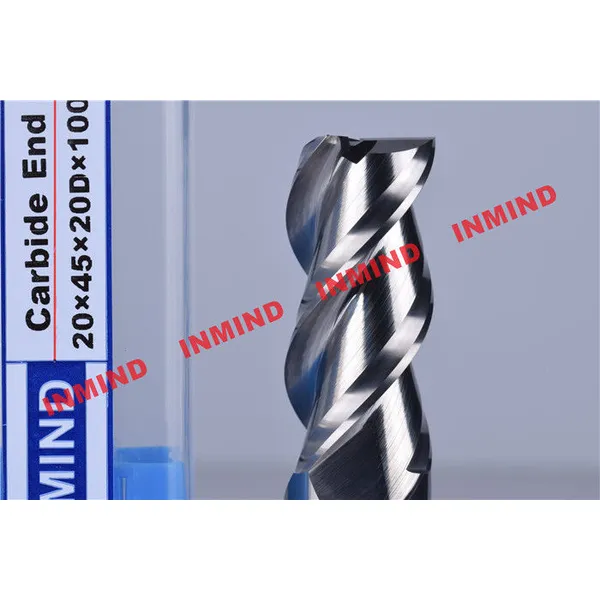

| 100mm | Name:Square End Mill | |

| 25mm | Type:Extra Long Type | |

solid carbide cutting tools,carbide milling cutters |

||

Solid Carbide Square End Mill For Aluminum For Steel

Description:

| Products Name | Solid Carbide Tapered Square End Mill With High Quality |

| Raw Material (HRC) | HRC45 , HRC55 , HRC60 , HRC65 |

| Coating Type | ALTIN , TIALN , TISIN , NACO |

| Size | Standard size or customized size based on customers |

| Logo | Your brand is welcomed to printed |

| MOQ | 10 pcs per size |

| Samples time | 5-7 dyas |

| OEM | Acceptable |

| Stock | Rich |

| Certification Available | Yes |

| Production Capacity | 300000 pieces per month |

| Payment terms | T/T, PAYPAL, WESTERN UNION,MONEY GRAM |

| Packing Details | Plastic pipe in carton box with full of bubble paper and foam with 30cm*25cm*25cm |

| TYPE | Material | MG grain size | CO | Flexural strength |

| HRC45 | YG10X | 0.7um | 10% | 3320N/mm2 |

| HRC55 | YL10.2 &WF25 | 0.6um | 10% | 4000N/mm2 |

| HRC60 | K44 &K40 | 0.5um | 12% | 4300N/mm2 |

| HRC65 | H10F | 0.5um | 10% | 4300N/mm2 |

| Coating Type | Hardness(HV) | Thickness(UM) | Oxidation Temp.(℃) | Friction Coefficient | Color |

| AlTin | 3200 | 2.5-3 | 900 | 0.3 | Black |

| Tialn | 2800 | 2.5-3 | 800 | 0.3 | Violet |

| TiSin | 3600 | 3 | 1000 | 0.45 | Copper |

| Naco | 42(GPA) | 3 | 1200 | 0.4 | Bule |

Advantages:

1.Low MOQ: Along with your promotional business very well.

2.OEM Accepted : We can produce any your design .

3.Logo: All products well packaged with or without labels , Customers required labels and logos are acceptable

4.Good Service : Clients are our Friends

5.Stock : Standard end mills are Rich in Stock .

6.Reasonable price:Best quality along with reasonable prices. Discount based on Quantity

7.Good Quality :Quality can be guaranteed with the CNC Machine and our serious QC .Good reputation in the market.

8.Fast & Cheap Delivery: UPS , EMS , TNT , FEDEX , DHL , ARAMEX are all accept based on Clients' Customs require

9.Payment Grading: You can pay 30% in advance first , then pay the rest 70% when we finished the goods before shipping

Order Guide:

Please check the below information on Placing orders

| 1 . Inquiry online , we will reply ASAP with our Catalogue |

| 2 . Confirm the exact size ( Cutting diameter , Flutes length , shank diameter and full length ) , material of your work pc , HRC , QTY , then we can send your our Best Quotation . |

| 3 . Confirm the exact test order details ( MOQ test QTY is 5 pcs per size ), payment terms , Express type , and we can send the Proforma Invoice to you |

| 4 . Pls send us the payment Confirmation to us ASAP after you made it , them we could arrange to start the produce for you ASAP . |

| 5 . Middle Production-send photos to show the production line which you can see your products in . Confirm the estimated delivery time again. |

| 6 . Confirm the exact Color of Package details , the exact delivery address , Receiver, post code and details before we finish the goods . |

| 7 . We will inform and send out your order to you ASAP after we finihsed them , Inform the tracking number by mail and check the status of the goods . |

| 8 . Order can be say “finish” when you receive the goods and satisfy with them |

| 9 . Feedback to Freedom about Quality , Service, Market Feedback & Suggestion. |

| 10 . We will show your feedbake to our engineers to do beter for you in the future for Long-term Cooperation |

1. Are you manufacturer? Do you have factory

We are Professional manufacturer ,we have more than 15 years experience in this field.

2. What machine you use? You can see TTB & ANCA &Michael Deckel& Rollomatic will be arrive warehouse at October grinding machines in our factory, also have Zoller detection machine &PG1000 Checking machine from USA. 3. Do you make OEM? Yes, we do. We have laser machine, can laser your logo and sizes on the body of milling cutter, also can print labels.

4. Will you attend International Exhibition? Yes, we had attended exhibitions in Germany(EMO), Indonesia, Malaysia .Russia. India, Thailand, Vietnam, Taiwan, etc. We are ready to go to America and Brazil in 2015. 5. Can you produce carbide Special Tool ? Yes We can. From 2013 year. Our factory main market is from standard end mills to special tools. Special tool according your drawing and sample 6. Have any certificate of your factory? Surely. Our factory pass SGS and ISO9001 Certification.